The climate emergency brooks no compromise: every human activity or artefact is either part of the solution or it is part of the problem.

I’ve worried about the sustainability of consumer electronics for some time, and, more recently, the shocking energy costs of big AI. But the climate emergency has also caused me to think hard about the sustainability of robots. In recent papers we have defined responsible robotics as

the application of Responsible Innovation in the design, manufacture, operation, repair and end-of-life recycling of robots, that seeks the most benefit to society and the least harm to the environment.

I will wager that few robotics manufacturers – even the most responsible – pay much attention to repairability and recyclability of their robots. And, I’m ashamed to say, very little robotics research is focused on the development of sustainable robots. A search on google scholar throws up a handful of excellent papers detailing work on upcycled and sustainable robots (2018), sustainable robotics for smart cities (2018), green marketing of sustainable robots (2019), and sustainable soft robots (2020).

I was therefore delighted when, a few weeks ago, my friend and colleague Michael Fisher, drafted a proposal for a new standard on Sustainable Robotics. The proposal received strong support from the BSI robotics committee. Here is the formal notice requesting comments on Michael’s proposal: BS XXXX Guide to the Sustainable Design and Application of Robotic Systems.

So what would make a robot sustainable? In my view it would have to be:

- Made from sustainable materials. This means the robot should, as far as possible, use recycled materials (plastics or metals), or biodegradable materials like wood. Any new materials should be ethically sourced.

- Low energy. The robot should be designed to use as little energy as possible. It should have energy saving modes. If an outdoor robot then is should use solar cells and/or hydrogen cells when they become small enough for mobile robots. Battery powered robots should always be rechargeable.

- Repairable. The robot would be designed for ease of repair using modular, replaceable parts as much as possible – especially the battery. Additionally the manufacturers should provide a repair manual so that local workshops could fix most faults.

- Recyclable. Robots will eventually come to the end of their useful life, and if they cannot be repaired or recycled we risk them being dumped in landfill. To reduce this risk the robot should be designed to make it easy re-use parts, such as electronics and motors, and re-cycle batteries, metals and plastics.

These are, for me, the four fundamental requirements, but there are others. The BSI proposal adds also the environmental effects of deployment (it is unlikely we would consider a sustainable robot designed to spray pesticides as truly sustainable), or of failure in the field. Also the environmental effect of maintenance; cleaning materials, for instance. The proposal also looks toward sustainable, upcyclable robots as part of a circular economy.

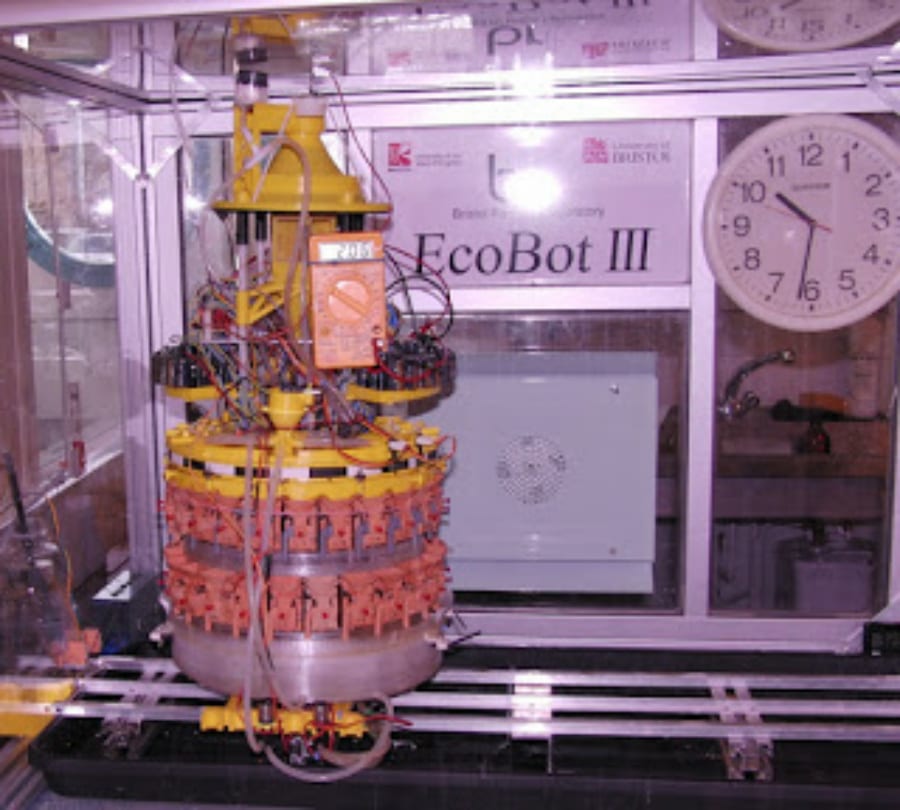

This is Ecobot III, developed some years ago by colleagues in the Bristol Robotics Lab’s Bio-energy group. The robot runs on electricity extracted from biomass by 48 microbial fuel cells (the two concentric brick coloured rings). The robot is 90% 3D printed, and the plastic is recyclable.

I would love to see, in the near term, not only a new standard on Sustainable Robotics as a guide (and spur) for manufacturers, but the emergence of Sustainable Robotics as a thriving new sub-discipline in robotics.

Alan Winfield is Professor in robotics at UWE Bristol. He communicates about science on his personal blog.

guest author

Alan Winfield is Professor in robotics at UWE Bristol. He communicates about science on his personal blog.